A contractor in large-scale floating oil and gas production systems commissions design drawings from in-house and external design teams distributed globally.

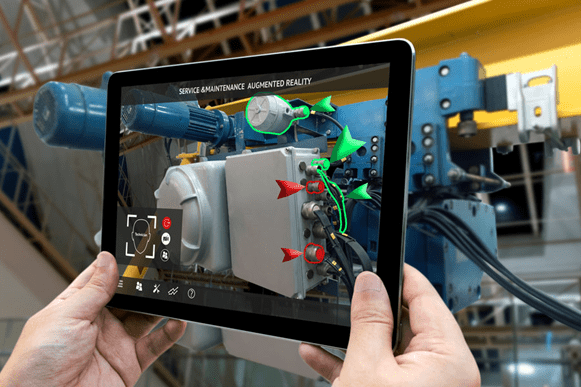

To reduce their deployment of expensive design experts to detect defects in design drawings, Alumnus deployed computational geometric algorithms for shape recognition, Rule engines and ML techniques to automate defect detection and drive the drawing remediation process.

With AutoCAD isometric drawings (several thousands) and higher-level designs called P&ID (Piping and Instrumentation Diagram) as input, the software detects possible design mistakes and deviations from the workflow methods of the organization. The work involved reading drawings into consistent data-structures, using Computational Geometric algorithms for shape recognition, Machine-learning for detection of deviations and imaginative User Interface to report them.

The solution has substantially reduced human-dependency for checking drawings and thereby has not only saved cost but also improved productivity of experts by capturing design errors earlier in the project life cycle.

Technology Stack:

Visual C#, .Net, MongoDB, Netdxf, MongoDB